We provide pulp-industry byproducts for valuable, sustainable solutions.

GP Pine Solutions is your trusted partner for quality pulp-industry byproducts and residues, such as Crude-Tall Oil (CTO) and Crude Sulphate Turpentine (CTS), that maximize resources and minimize waste. With a focus on long-term partnerships, we are dedicated to helping you drive both profitability and environmental stewardship, so you can meet evolving market demands more responsibly.

about us

Built on expertise, backed by reliability.

We leverage decades of expertise and the extensive infrastructure of Koch and Georgia-Pacific to deliver our products with reliable consistency. As one of the largest U.S. suppliers of pulp-industry byproducts and residues, we cultivate partnerships by aligning with your unique needs and providing dependable solutions.

Proven Partnership

GP Pine Solutions combines innovative thinking with market insights to deliver tailored solutions that help you stay ahead in a constantly shifting landscape.

We design strategies that not only address complex challenges but also unlock opportunities for growth, ensuring every solution integrates with your business vision.

Our team’s responsiveness and agility empower you to quickly adapt in fast-changing markets, maintaining a competitive edge.

With a robust portfolio of GP-owned crude tall oil plants and numerous additional collection points, our extensive infrastructure ensures consistent, scalable delivery across diverse markets.

our process

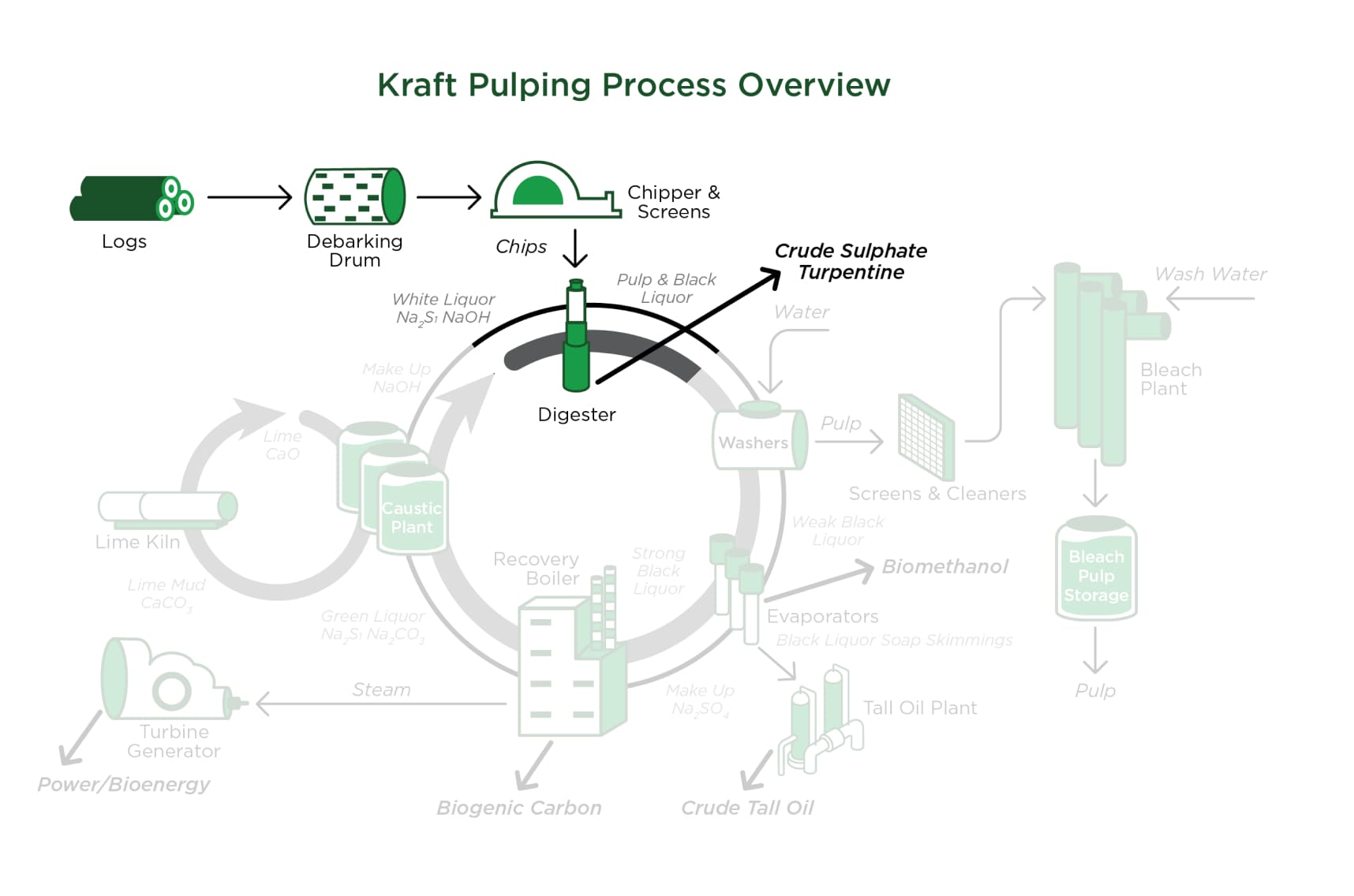

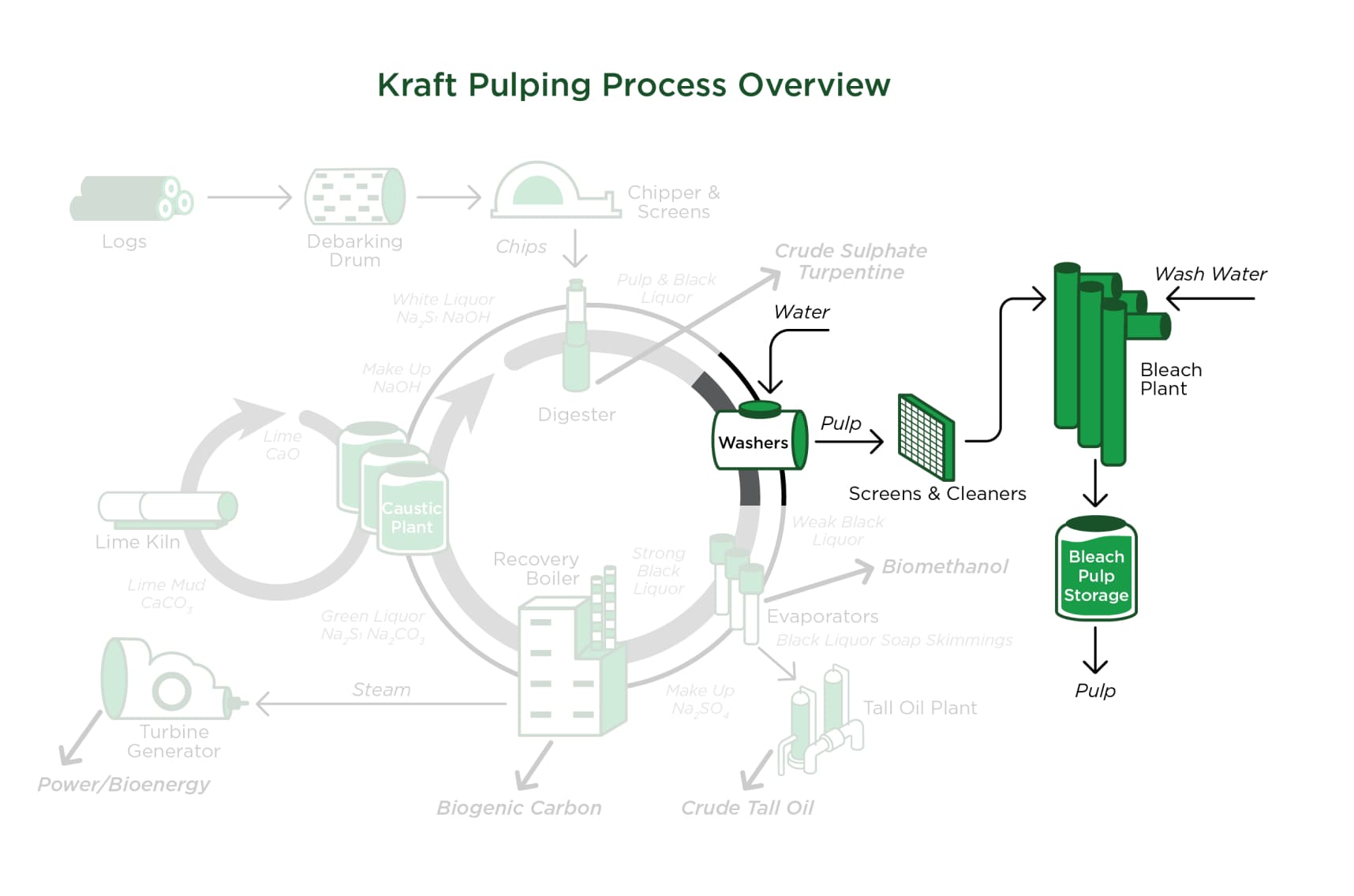

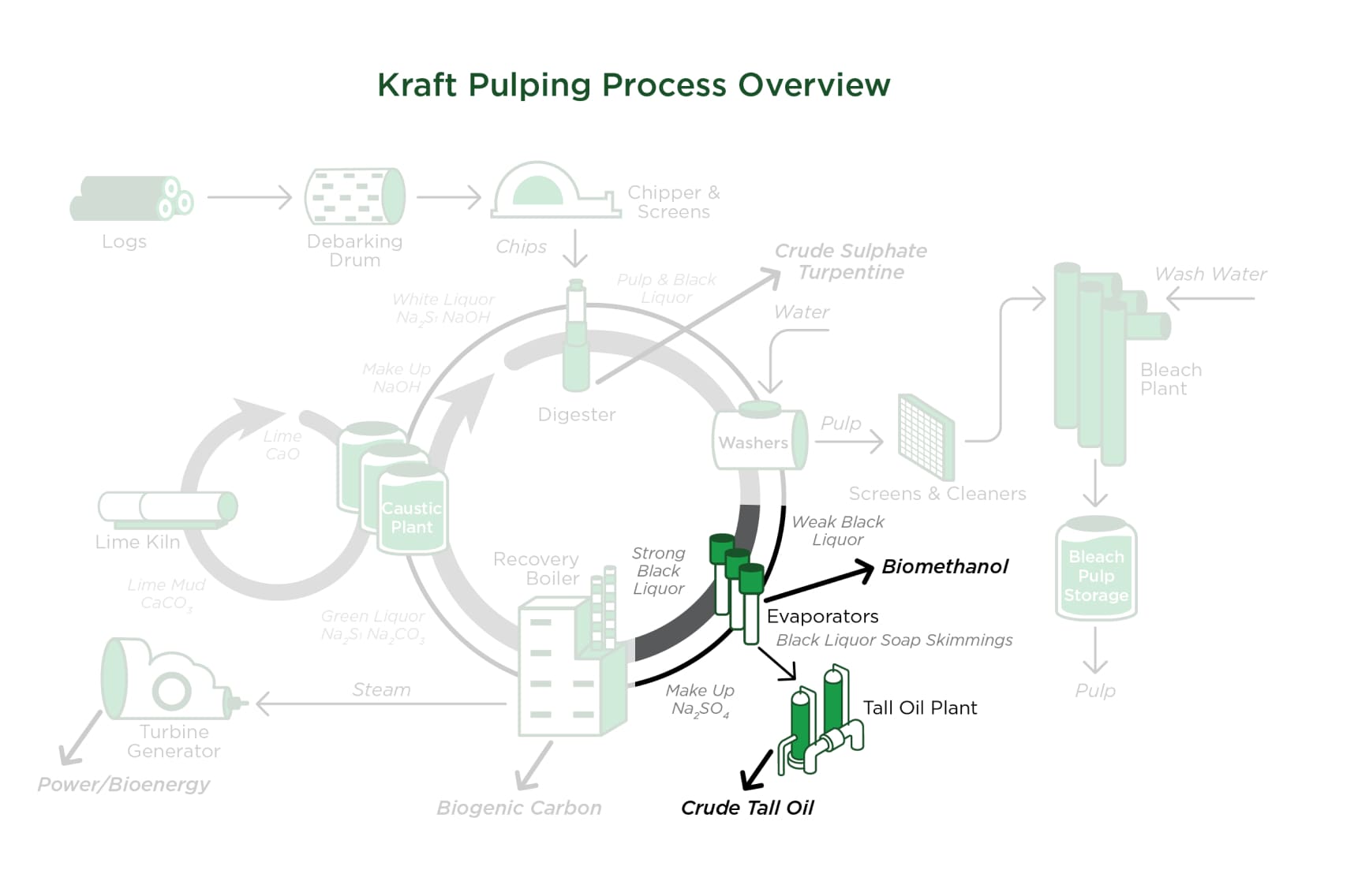

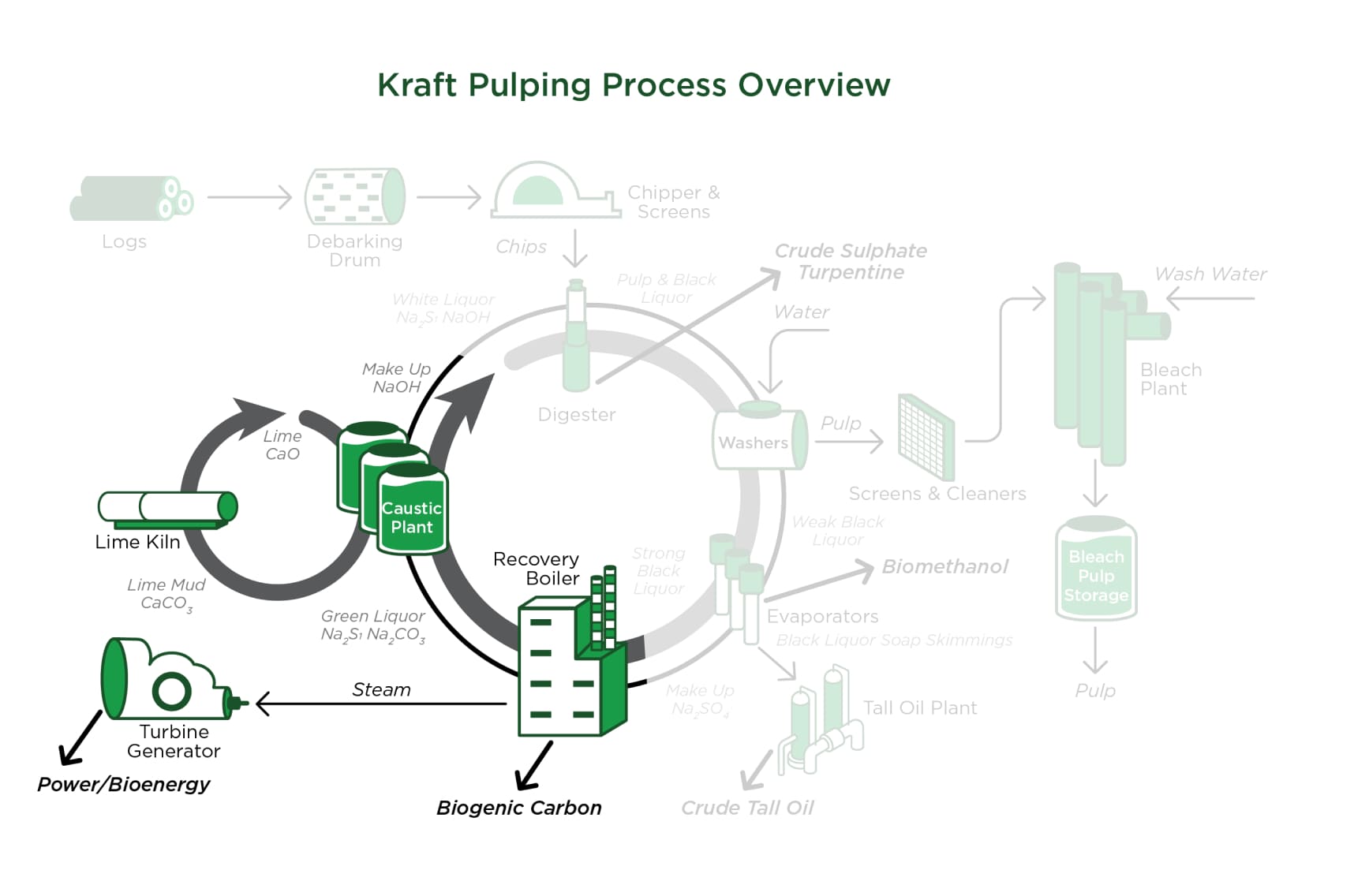

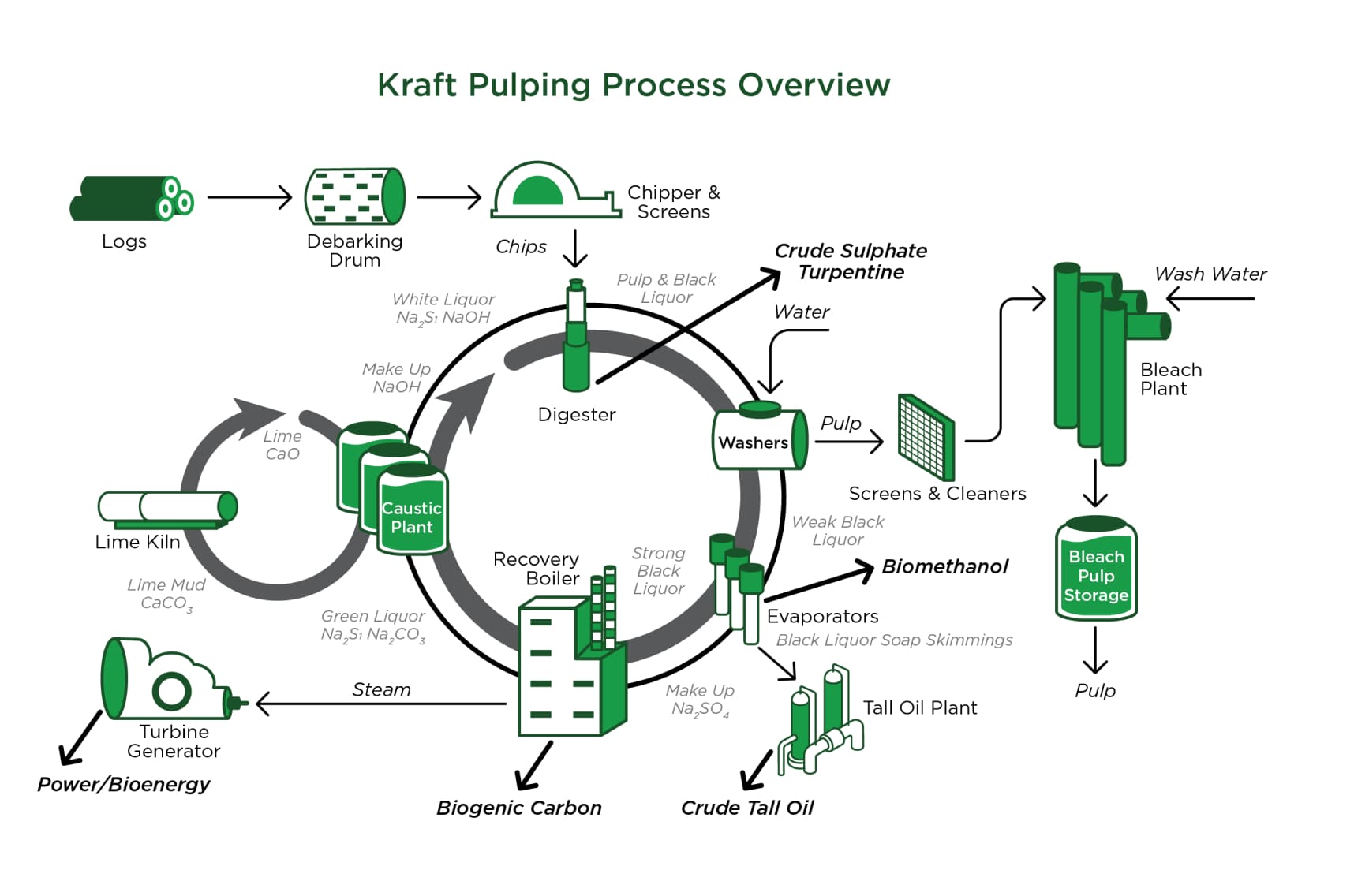

Where do our byproducts come from? The Kraft Pulping Process.

Wood Digestion

Locally sourced pine tree wood chips are processed into pulp in a closed-loop chemical process known as the liquor cycle. During this process, a “cooking liquor” breaks the wood chips into pulp.

Washing & Black Liquor Concentration

The pulp is removed and further processed for downstream applications like absorbent hygiene products or papermaking.

Recovery Boiler

The rosin acids, fatty acids, and turpentine that naturally occur in the wood are also released. GP recovers these wood extractives from the liquor cycle in the form of Crude Tall Oil (CTO) and Crude Sulphate Turpentine (CTS).

Causticizing & White Liquor Recovery

The remaining cooking liquor is fully recycled in the closed-loop process and used to cook more wood chips again and again.

completed

The remaining cooking liquor is fully recycled in the closed-loop process and used to cook more wood chips again and again.

sustainability

We are rooted in responsibility.

GP Pine Solutions maximizes resources and reduces waste by utilizing every part of the tree. By transforming byproducts and residues of pulp production into value-added materials, we demonstrate an efficient use of natural resources.

In addition, Georgia-Pacific sources all of its wood using its due diligence system, meeting the standards of SFI® Certified Sourcing, PEFC Controlled Sources, and FSC® Controlled Wood (SFI-00007, PEFC/29-31-221, FSC-C108208). With decades of transparent practices, we deliver solutions that can help support your stewardship goals.

Let's partner to make progress together.

Discover the value of a partnership with GP Pine Solutions. Our proven expertise and forward-thinking solutions empower your business to thrive in an evolving marketplace.

Fill out the form to start the conversation on how we can work together to achieve your goals.